Corva Delivers Efficiency Gains and Greater Drilling Predictability in Egypt

Addressing Critical Drilling Challenges in Egypt

An operator in Egypt faced significant drilling obstacles, including erratic torque and vibrations that caused lateral and stick-slip issues. Wellbore instability led to partial losses, gas kicks, and formation damage, while differential sticking from pressurized zones disrupted mud flow, creating further delays and risks. These challenges demanded a comprehensive solution to improve drilling efficiency and operational predictability.

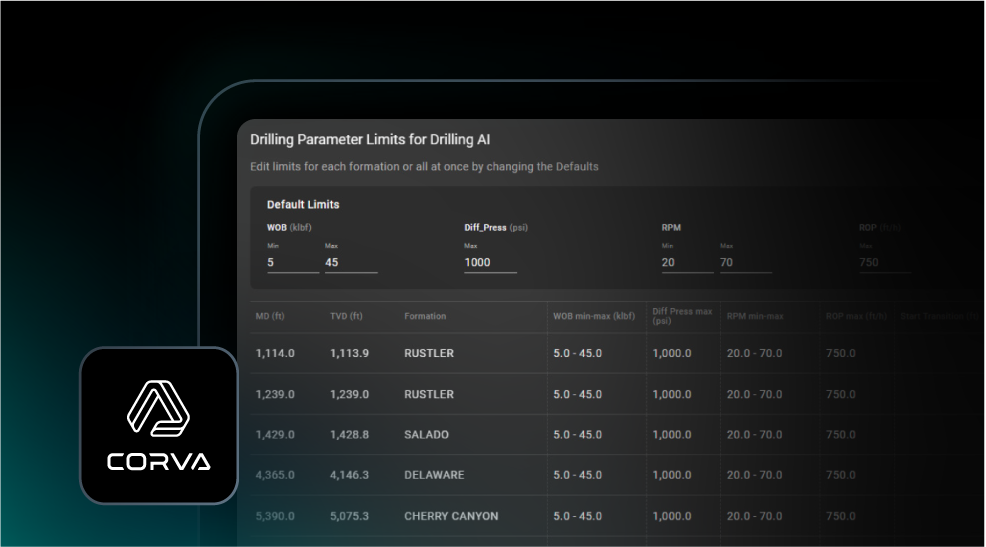

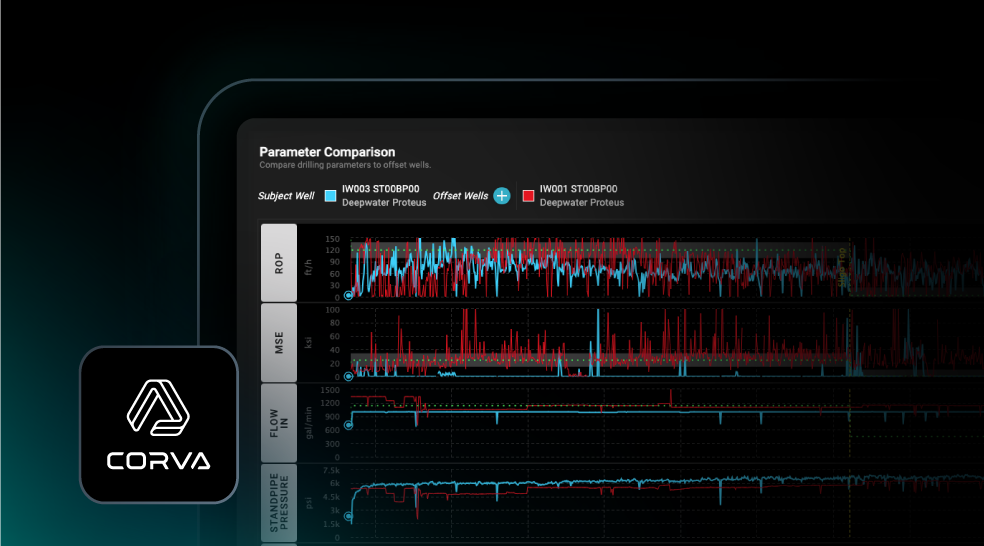

Transforming Drilling Operations with Corva’s Technology

By leveraging the Corva Platform and i-Trak™, the team implemented advanced solutions to mitigate dysfunction, optimize torque and drag, and safeguard boundary conditions. Automated monitoring and real-time adjustments minimized vibrations, enhanced ROP, and reduced reaming times, significantly improving operational stability. These efforts saved 4.3 days, cut costs by $350K, and delivered a 17% increase in rotary ROP.