Safety rules the seas, making “steady as she goes” the mantra for offshore drilling. But it’s a constant balancing act to prioritize crew and environmental safety with the capital outlay required for offshore rigs and drilling operations. Whether you are focused on North Sea, Gulf of Mexico, Brazil, or West Africa, Corva’s suite of drilling and completion apps will help you drill more efficiently, optimize rotary and directional ROP, and minimize NPT. At the same time Corva equips your team with powerful analytics to identify hazardous equipment and subsurface conditions in real-time and ensure safe operations.

Here are just five Corva apps that will help drillers and crews rapidly achieve higher levels of operational efficiency, maintain consistency, and track critical key performance indicators.

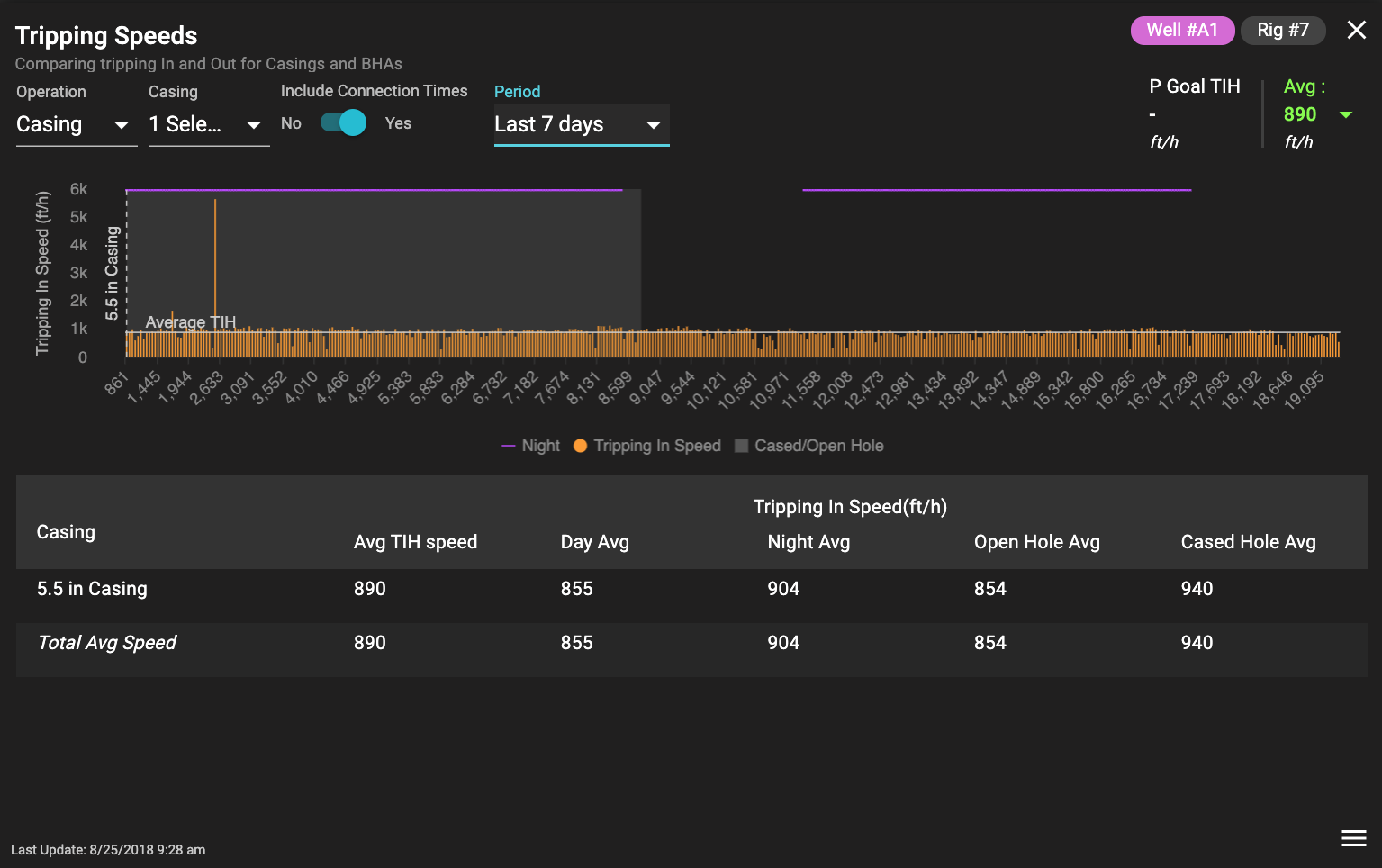

Tripping Speeds and Casing Connections

Trimming down tripping and casing connection times can add up to significant operational efficiency and savings on rig time. Corva allows users to set goals then track KPIs for tripping in and out BHAs with the ability to compare day and night shifts. Analyze connection times alongside tripping speeds with a bar chart breakdown of individual joints or stands. During completions, this app can be used to track and improve casing connection times as crews pick up casing stands from the derrick or deck.

Figure 1: Corva’s Tripping Speeds App

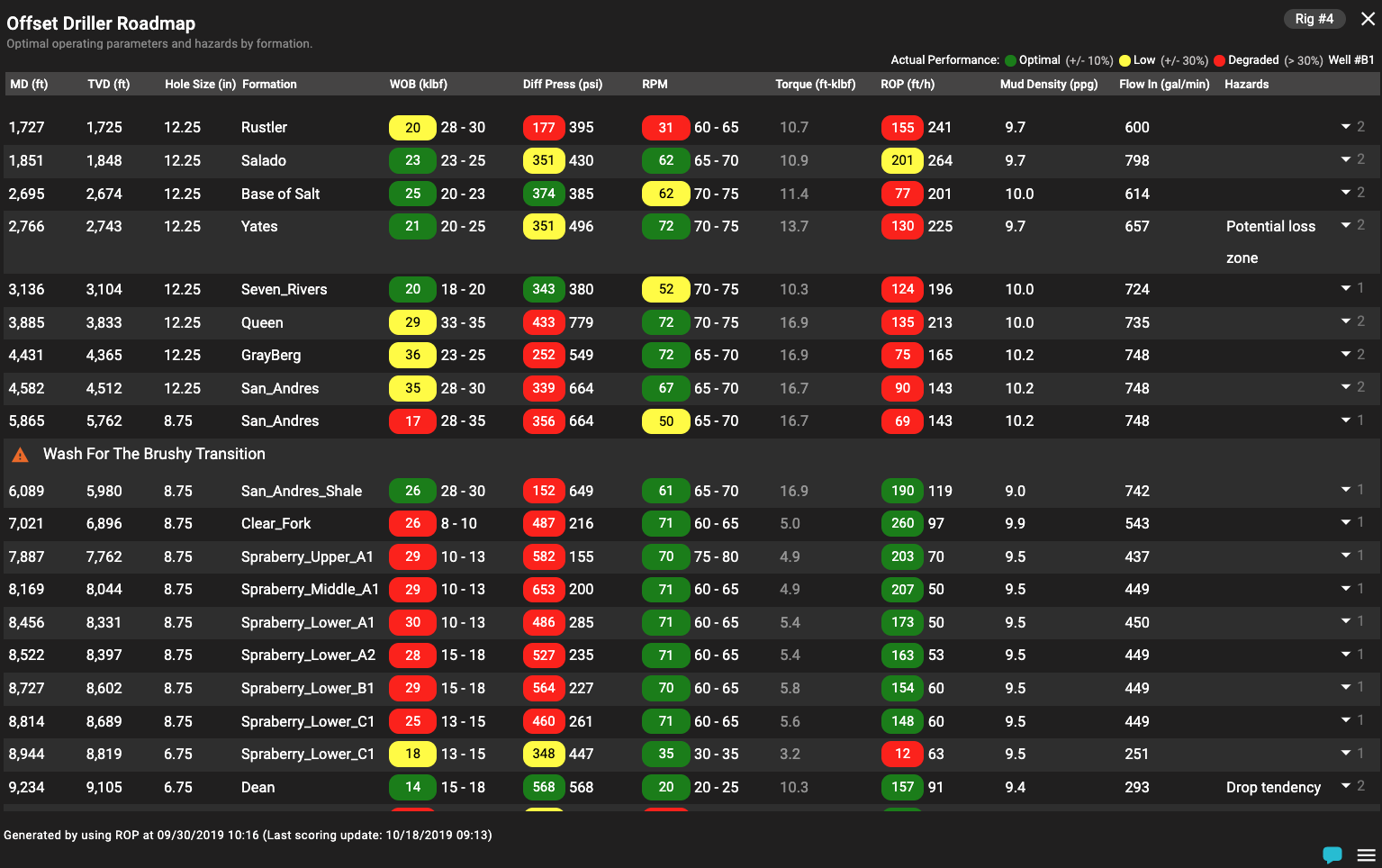

Driller’s Roadmap

Easily analyze offset wells for the platform or template to build a continuously improving array of best-performing drilling parameters. Corva’s Driller’s Roadmap mines large volumes of historical well and BHA data, freeing your team from time-consuming manual analysis by instantly identifying optimal parameters for a given formation. It is used to set the starting weight on bit, torque, RPM, and other parameters for formation tops using best-in-class performance and BHA configuration.

Figure 2: Corva’s Driller’s Roadmap

Parameter Comparison

Using the Driller’s Roadmap or Corva’s Metrics Engine, users can mine offsets in the field to find the combination of drilling parameters that yield optimal ROP through a hole section with only one run. The Parameter Comparison app enables drillers to implement those parameters and recreate one run sections. This is achieved by visualizing the target well’s parameters alongside the best-performing parameters (RPM, WOB, Torque, MSE, etc.), enabling the driller to stay on target by anticipating upcoming parameter changes with instant feedback on deviation. As a result, you can prevent overly aggressive settings that lead to costly trips without sacrificing ROP.

Figure 3: Corva’s Parameter Comparison App

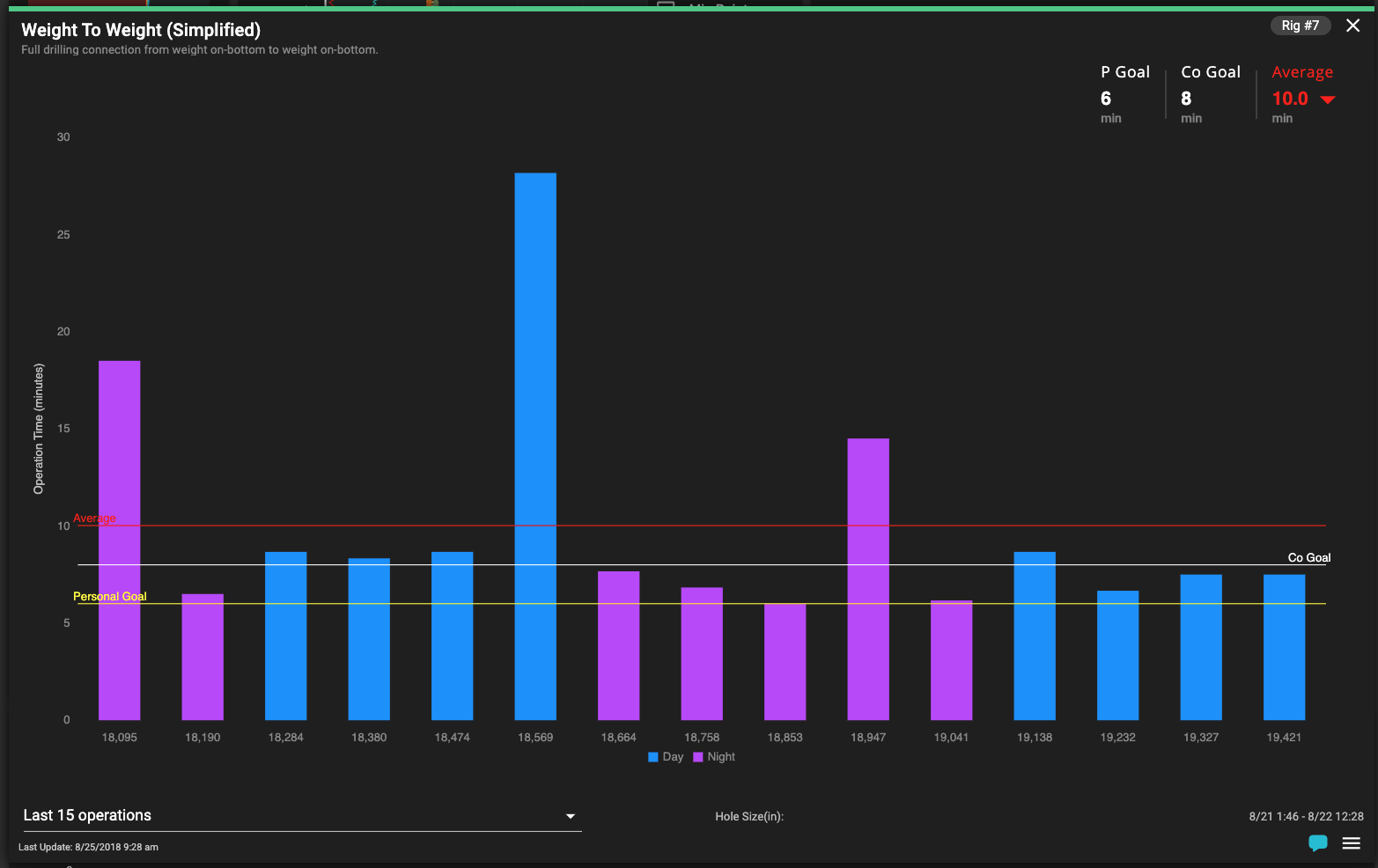

Connection Times

Corva’s Connection Times app automatically tracks on bottom to slips, slips to slips, slips to on bottom, and weight to weight. At a glance, users see the times for the current operation and averages for the day, and platform with a 30-day trend. These KPIs provide crews with safe time targets while also trimming significant time and money on connections.

Figure 4: Corva’s Connection Times App

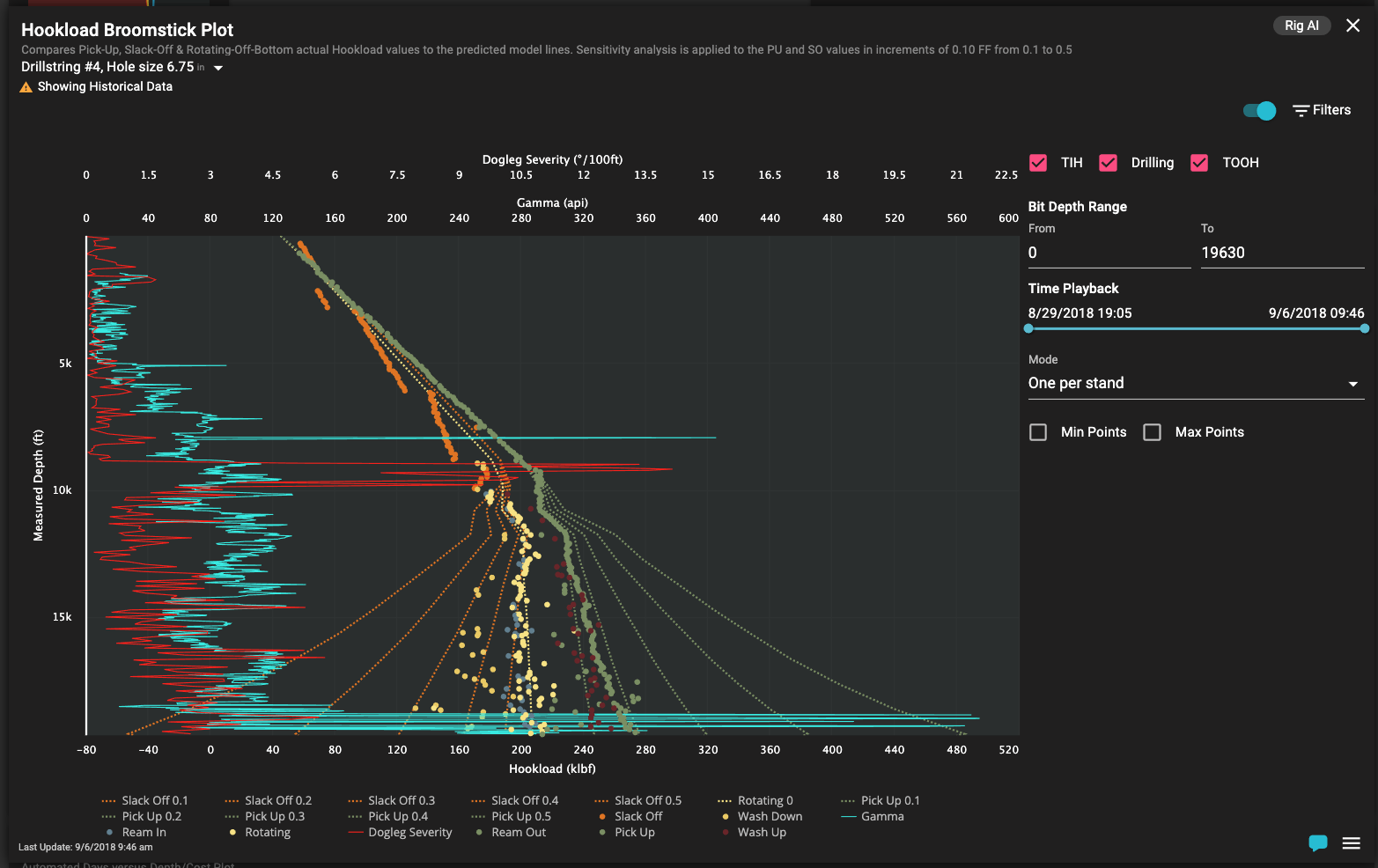

Torque & Drag Broomstick Plot

Corva completely automates the torque and drag modeling required to create a Hookload Broomstick plot, which is rendered on the fly to show the current Pick-Up, Slack-Off, & Rotating-Off-Bottom Hookload values in comparison to predicted model lines. The plot enables users to rapidly identify potential hole problems and poor hole cleaning while drilling or tripping. As a result, drillers gain valuable real-time insight that allows them to avoid buckling and optimize ROP and trip times.

Figure 5: Corva’s Hookload Broomstick Plot

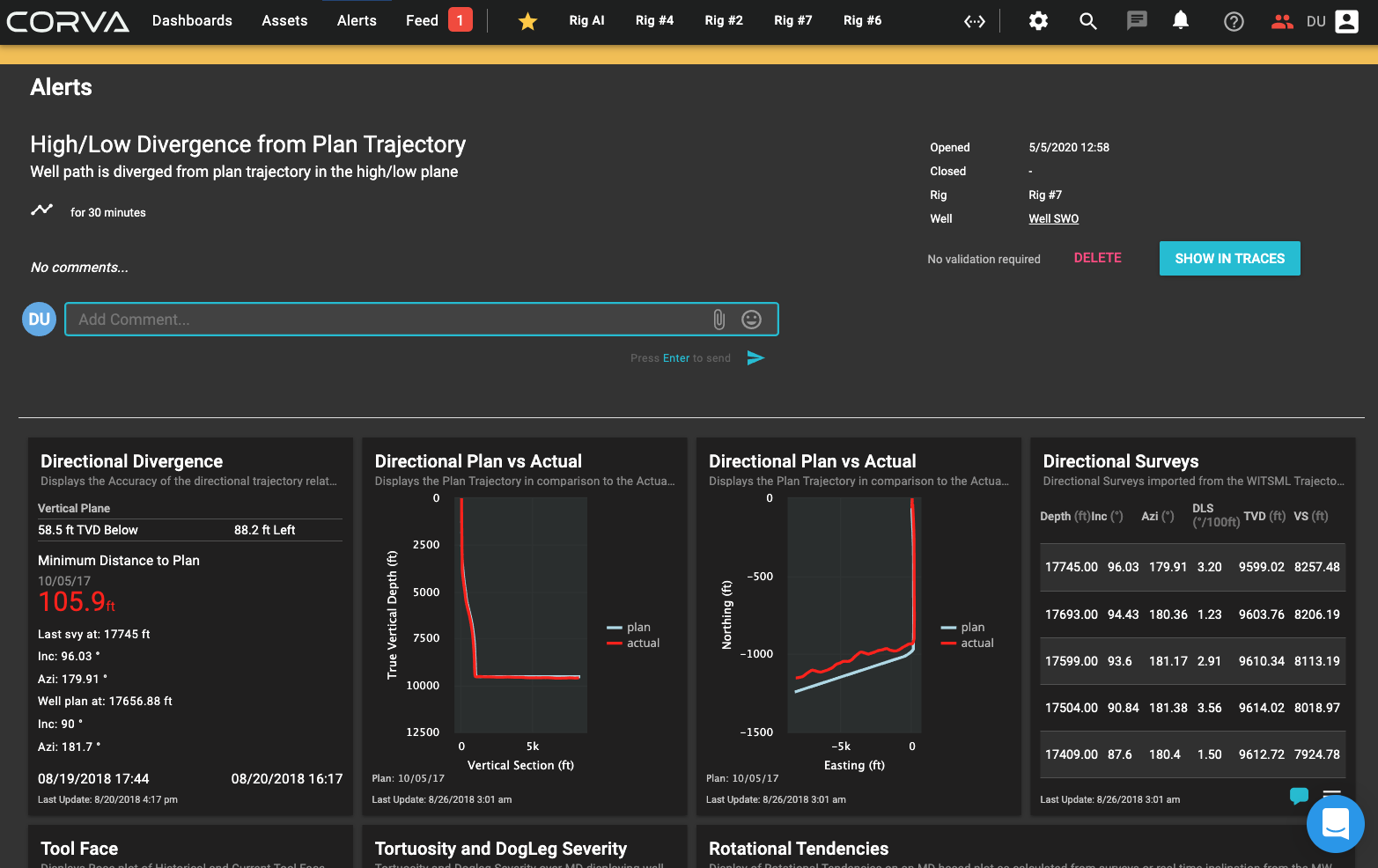

Real-Time Alerts

From connections and tripping to equipment calibration and malfunction, your team maintains dozens of standard operating procedures in order to drive efficiency and consistency. Corva’s real-time drilling optimization platform lets your team define organizational and industry standards for simple or highly complex procedures, then enforce them with our Procedural Compliance app and automated alerts(delivered by in-app notification, text message, or e-mail). Plus, hazard avoidance alerts can also be configured that leverage advanced algorithms to detect pressure trends and early warning signs of a washout, enabling drillers to prevent twist-offs and other hazards.

Figure 6: Corva’s Real-Time Alerts Dashboard

With Corva, offshore operators no longer have to trade speed and capital expenditure for safety. Armed with these five apps (and nearly 60 other drilling apps built to optimize workflows across the rig and platform), your team can have the best of both worlds.